In the pharmaceutical and cosmetic industry, every production process must be validated with documented tests according to the standards of the GMP (Good Manufacturing Practice) and GAMP (Good Automated Manufactuing Practice) guidelines. It is also necessary to comply with the requirements of the national bodies such as AIFA (Agenzia Italiana del Farmaco), EMA (European Medicines Agency), Swiss Medic (Swiss Agency for Therapeutic Products), SFDA (Saudi Food & Drug Authority).

The manufacturers of cosmetic and pharmaceutical products can obtain the permission to sell such products only by providing strictly controlled and binding qualification protocols to the above-mentioned bodies.

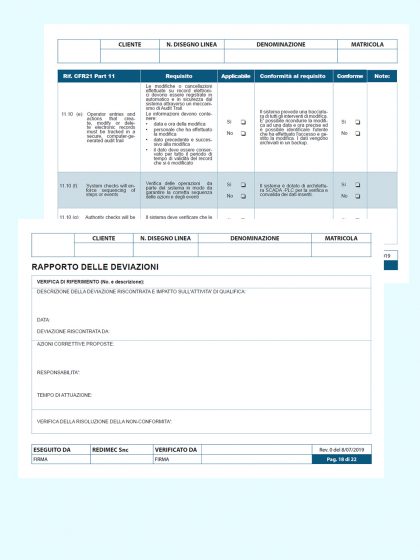

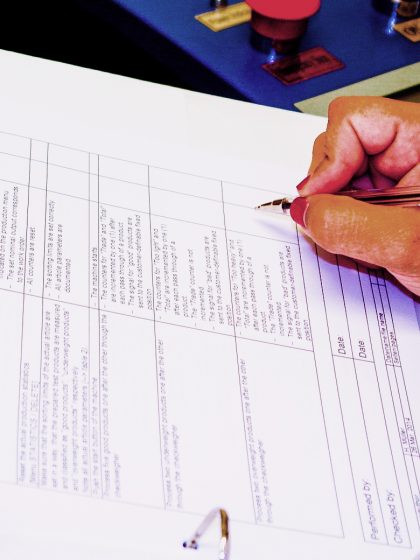

During the qualification process, the protocols are filled in to carry out all the necessary checks.

Redimec is able to draw up all the necessary documents to validate pharmaceutical or cosmetic production lines, machinery or equipment as well as pharmaceutical and/or cosmetic products in close collaboration with its customers, relying on internal staff with a degree in Pharmaceutical Science.

The validation process consists of the following checking phases:

• Functional Specification (F.S.)

• Design Qualification (D.Q.)

• Installation Qualification (I.Q.)

• Operational Qualification (O.Q.)

• Performance Qualification (P.Q.)

• Maintenance Qualification (M.Q.)

• Standard Operating Procedure (S.O.P.)

• Computer System Validation (C.S.V.)

• Cleaning Validation

• Factory Acceptance Test (F.A.T.)

• Site Acceptance Test (S.A.T.)

• User Requirements Specifications (U.R.S.)

• Software Design Specifications (S.D.S.)

• Hardware Design Specifications (H.D.S.)

We ensure the best support: our validation personnel is able to provide our customers on site-assistance during the certification and validation process both in Italy and abroad.